Multimaterial 3D printing with a twist

Rotational multimaterial printing of helical filaments for soft robotics and structural composites

By Leah Burrows

January 18, 2023

Scientists that seek to mimic the helical structures that constitute biological systems must create new tools that can precisely pattern different materials with programmable local composition, architecture, and properties.

Researchers from the Harvard John A. Paulson School of Engineering and Applied Sciences and the Wyss Institute for Biologically Inspired Engineering at Harvard University have developed a rotational multimaterial 3D printing method for creating helical filaments. Using this new approach, the team designed and fabricated artificial muscles and springy lattices for use in soft robotics and structural applications.

The team's research is published in Nature.

"Our additive manufacturing platform opens new avenues to generating multifunctional architected matter in bio-inspired motifs," said Jennifer Lewis, the Hansjorg Wyss Professor of Biologically Inspired Engineering at SEAS and senior author of the study.

Lewis is also a Core Faculty member of the Wyss Institute.

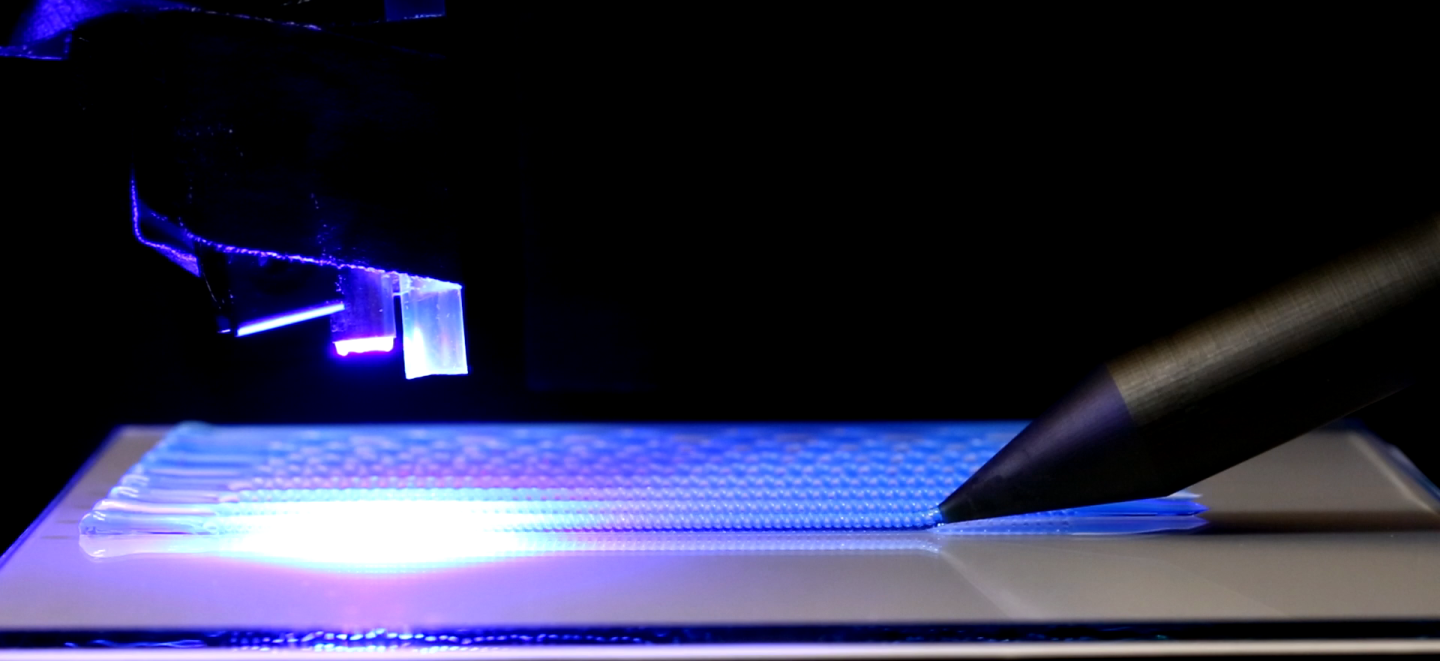

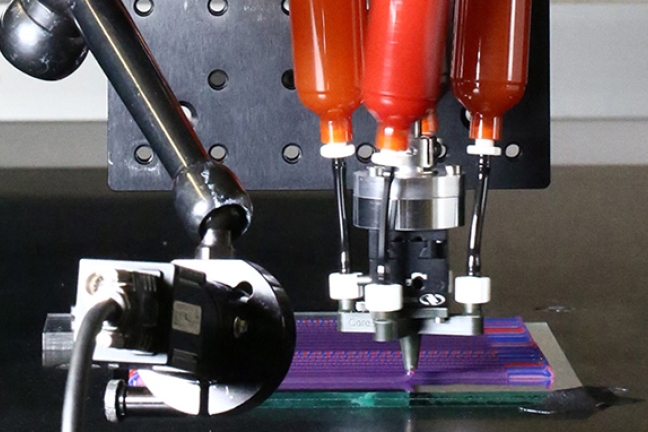

Their new printhead consists of four ink cartridges, each of which can contain different materials. The inks are then fed through a complex nozzle that allows multiple materials to be printed simultaneously. As the nozzle rotates and translates, the extruded inks form a filament with embedded helical features.

"Rotational multimaterial printing allows us to generate functional helical filaments and structural lattices with precisely controlled architecture and, ultimately, performance," said Natalie Larson, a postdoctoral fellow at SEAS and first author of the study.

In collaboration with David Clarke, the Extended Tarr Family Professor of Materials, the team printed artificial muscles in the form of helical dielectric elastomer actuator filaments that can contract under an applied voltage. The conductive electrodes form intertwining helices encapsulated in a soft elastomer matrix. By tuning how tightly those helical electrodes are coiled, one can program the contractile response of these actuators.

The team also designed structural lattices with varying stiffness by embedding stiff helical springs within a soft, compliant matrix—like metal springs in a soft mattress. The overall stiffness of the material can be tuned by tuning the tightness of the springs inside the matrix. These tunable helical structures could be used to make joints or hinges in soft robotic systems.

The printhead consists of four ink cartridges, each of which can contain different materials. The inks are then fed through a complex nozzle that allows multiple materials to be printed simultaneously.

Next, the team aims to harness the capabilities of this novel 3D printing method to create even more complex structures. "By designing and building nozzles with more extreme internal features, the resolution, complexity, and performance of these hierarchical bioinspired structures could be further enhanced," said Larson.

The research was co-authored by Jochen Mueller, Alex Chortos, and Zoey Davidson at SEAS. It was supported by the National Science Foundation under MRSEC (DMR- 2011754), NSF Designing Materials to Revolutionize and Engineer our Future (DMREF-15-33985), the Vannevar Bush Faculty Fellowship Program, sponsored by the Basic Research Office for the Assistant Secretary of Defense for Research and Engineering through the Office of Naval Research Grant N00014- 21-1-2958, and the GETTYLAB.