Programming Robots with Rubber Bands

New approach uses robot's physical structure for function

By Anne J. Manning

October 14, 2025

Key Takeaways

- A Harvard team has demonstrated that robots can be designed to react to their environment and perform tasks by programming intelligence into their structure.

- They created a robot capable of autonomously moving away from obstacles, with minimal electronics.

- The work presents an alternative to traditional robotic sensing and control systems.

From sorting objects in a warehouse to navigating furniture while vacuuming, robots today use sensors, software control systems, and moving parts to perform tasks. The harder the task or more complex the environment, the more cumbersome and expensive the electronic components.

Robots today use sensors, software control systems, and moving parts to perform tasks. Mechanical engineering researchers at SEAS think there’s another way to design robots: Programming intended functions directly into a robot’s physical structure, allowing the robot to react to its surroundings without the need for extensive on-board electronics.

Mechanical engineering researchers in the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS) think there's another way to design robots: Programming intended functions directly into a robot's physical structure, allowing the robot to react to its surroundings without the need for extensive on-board electronics.

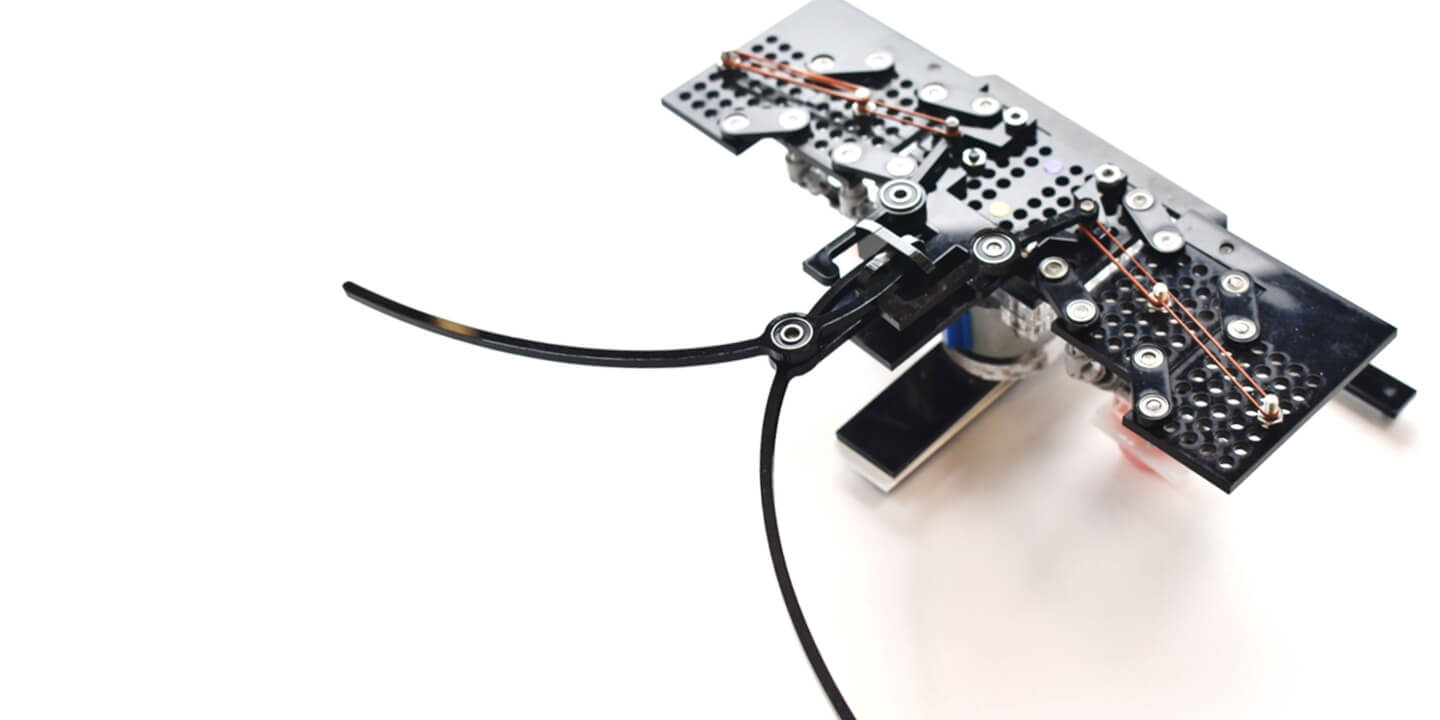

A team from the lab of Katia Bertoldi, the William and Ami Kuan Danoff Professor of Applied Mechanics at SEAS, designed a proof-of-concept walking robot with just four moving parts connected by rubber bands and powered by one motor. With its movements programmed via the placement of the rubber bands, the robot can find its way through mazes and avoid obstacles; its movements change based only on how it is touched or pressed by its environment, with no electronic brain. They also show that the same mechanical programming can be used to make a robot capable of sorting objects by mass.

The demonstration could spark new inquiry into fundamentals of robotic design, potentially leading to smaller, simpler robots that can perform a variety of functions.

Published in Proceedings of the National Academy of Sciences ![]() , the work was led by Leon Kamp, a graduate student in Bertoldi's lab whose secondary graduate study is in Critical Media Practice. Trained in engineering and architecture, Kamp turned to robotics as a practical application of his interest in form, material, and mechanics. He wondered if robotic intelligence could be infused into structure using mechanical principles.

, the work was led by Leon Kamp, a graduate student in Bertoldi's lab whose secondary graduate study is in Critical Media Practice. Trained in engineering and architecture, Kamp turned to robotics as a practical application of his interest in form, material, and mechanics. He wondered if robotic intelligence could be infused into structure using mechanical principles.

"This is kind of an extreme version of 'form follows function,' where functionalities like memory, adaptability and intelligence can be enabled by geometry and material parameters," Kamp said.

Kamp and colleagues built their robotic mechanism from a chain of flat plastic blocks joined by levers and rubber bands. The stretching of the rubber bands assigns a certain energy cost to rotating each lever. The movement of the mechanism can be "programmed" as it follows the order of rotations that has the lowest energy cost. By attaching a leg to this mechanism, they built a robot that can walk forward and backward using one motor for different configurations of rubber bands.

This physical programming allows the robot to passively sense and respond to forces from its environment. It "feels" its surroundings via a pair of antennae attached to the front. When one antenna hits an obstacle, the robot responds and adapts from walking straight to turning away. It can autonomously navigate mazes or move away from obstacles.

In another configuration, the mechanism can be used to automatically sort objects based on their mass. In this case the rubber bands are used to "program," where objects are picked up and dropped off at different locations for specific targeted masses.

While the mechanism can only accomplish a small number of simple tasks, the concept could be expanded to robots that move faster or jump over obstacles. In the future, robots like this could be made of flexible materials that are lightweight and easy to manufacture. Such designs could lead to autonomous machines that are physically intelligent and rely on fewer electronics or traditional control systems to function.

Authorship, funding, disclosures, ownership

The paper was co-authored by Mohamed Zanaty, Ahmad Zareei, Benjamin Gorissen, and Professor Robert J. Wood.

The research received federal support from the National Science Foundation through the Harvard Materials Research Science and Engineering Center grant (DMR-2011754), and the Army Research Office Multidisciplinary University Research Initiative program (W911NF-22-1-0219).