UV formation with self-healing silicon elastomers for 3D printing

Novel responsive BBE polymer can be shaped and twisted into a permanent geometric form using UV illumination

By Carole H. Mezian

October 18, 2025

A solvent-free process was used to create a novel class of responsive polymers called bottlebrush elastomers (BBEs), which is characterized by its unusually ultrasoft and flexible properties with varying strength, according to how many spacer units are used and the type of spacer used in the development of the elastomer, and with the use of UV illumination to form shapes. The research development of this responsive elastomer vs. conventional elastomer has the potential to significantly advance current products, and to develop new soft matter applications.

BBEs resemble the structure of a "bottlebrush" where the molecular architecture is a densely grafted backbone with high-density side-chains, much like the bottle brush plant in terms of design. This makes the polymer, or elastomer, sturdy, but it also includes properties to include low electrical conductivity.

Researchers at the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS), first-author on this paper Miao Huo, a postdoctoral researcher in Materials Science and Mechanical Engineering, and David R. Clarke, the inaugural holder of the Extended Tarr Family Professor of Materials, present a novel class of BBEs that combine tunable mechanical properties, self-healing capabilities, and recyclability.

The research is published in the American Chemical Society Publications ![]() .

.

Applications with Shape Morphing

The bottlebrush-structured ultrasoft elastomer can transform into any geometric shape. BBEs are based on C−S (carbon sulfur) bonds, which enhances the material's rigidity where the bonds also make the material resistant to degradation, like corrosion or rust. The material's resistance to corrosion improves by forming a protective layer that shields against environmental aggressors like moisture and oxygen.

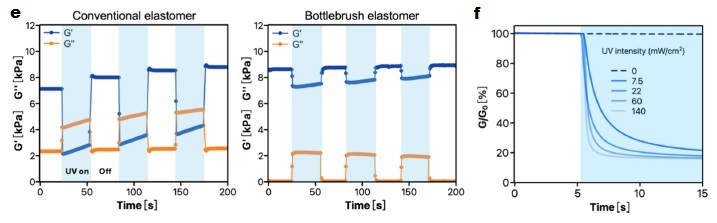

The above video demonstrates its remarkable shaping where the researchers used an elastomer strip (Figure a) cut it in half, and completely separated it. The two pieces were loosely re-aligned and re-joined together. UV irradiation was applied for approximately 10 seconds while holding the flat, bent, or coiled shape, which then the two elastomer pieces are "grafted," resealed, and self-healed within seconds. The grafted BBE retained its hardness, strength, and new shape as a single piece after the UV light was removed. This resealing process recovers approximately 86% of its original hardness after UV exposure. Conventional elastomers have no response to UV irradiation as shown in Figure e. In Figure f, the intensity of UV illumination is shown in the solid lines, and the relaxation of the elastomers occurs within 5 seconds. The dashed line represents the elastomer applied by no UV illumination.

The importance of this development using a responsive BBE application to product development include: flexible devices and electronics (e.g., dielectric elastomer actuators or smart material systems for soft robotics, artificial muscle, etc.), soft robotics, medical devices, and biomedical materials. This also enables the responsive BBE to be developed as an advanced material that mimics biological systems as soft artificial tissue with fewer or no repeat surgeries (e.g., human ears) as flexible implantable devices (e.g., a brain shunt, for building heart tissues and structures, surgical mesh for a hernia, etc.).

Applications in 3D Printing

The solvent-free responsive bottlebrush elastomers are ideal for 3D printing ink in digital light processing (DLP) devices that can create complex shapes and structures. Blending pigment particles into the elastomer matrix, multicolored 3D printing inks were prepared, and the printed objects were well-defined with high resolution. This is particularly highlighted and useful seen in Figure b, using a 3D printer to create replacement ears using various pigments, which suggests that a broad range of colors can be used to create shapes. Since the material can undergo shape morphing when formed into any geometric shape using UV light, which fixes the new shape upon curing, Figure c, demonstrations include the transformation of flat sheets into standing flowers and other intricate designs that showcase their potential in soft robotics and deployable devices. These features point to potentiality gateway for 4D printing ink.

Recycling Process

The printed BBE also has a recycling process to degrade the printed elastomer into a liquid state, where it can be then separated from pigments as shown in Figure d. This highlights the potential for sustainable use in additive manufacturing, enabling the separation and reutilization of degradated products.

Authorship, funding, disclosures, ownership

The research was supported by the National Science Foundation through the Harvard University Materials Research Science and Engineering Center grant DMR-2011754.