Building Soft Materials Using Surface Tension

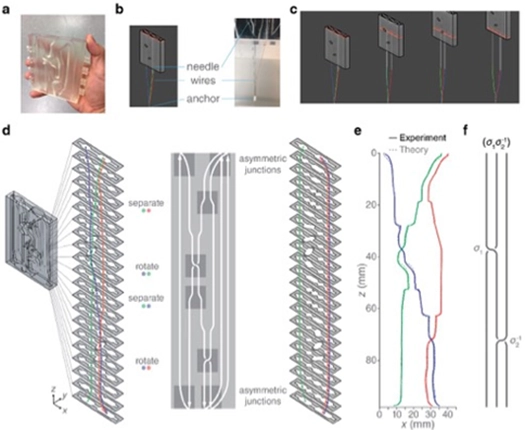

A team at the Harvard MRSEC led by Manoharan and Brenner has developed a way to build materials using surface tension. The method takes advantage of the "Cheerio effect": the tendency of floating objects (like Cheerios) to deform the surface of a liquid (like milk), and to exert forces on one another. Using a 3D-printed device with internal channels that fill with water, the team showed that objects that float inside the channels can be steered by moving the device up and down. With the help of a numerical model that can predict the forces on the floating objects, devices can be printed that move the objects in complex patterns. The method could be used to assemble small wires or colloidal particles into structured materials for electronic or optical applications.

Publication:

Zheng, Faaborg, Sherif, Falk, Hajian, Xiao, Hartig, Bar-Sinai, Brenner, and Manoharan, "3D-printed machines that manipulate microscopic objects using capillary forces," preprint (2021)

Vinothan N. Manoharan (Applied Physics, Materials, & Mechanical Engineering) and Michael P. Brenner (Applied Math)

2021-2022 Harvard MRSEC (DMR-2011754)