Rubber-Glass Nanocomposites via Mixed Emulsions

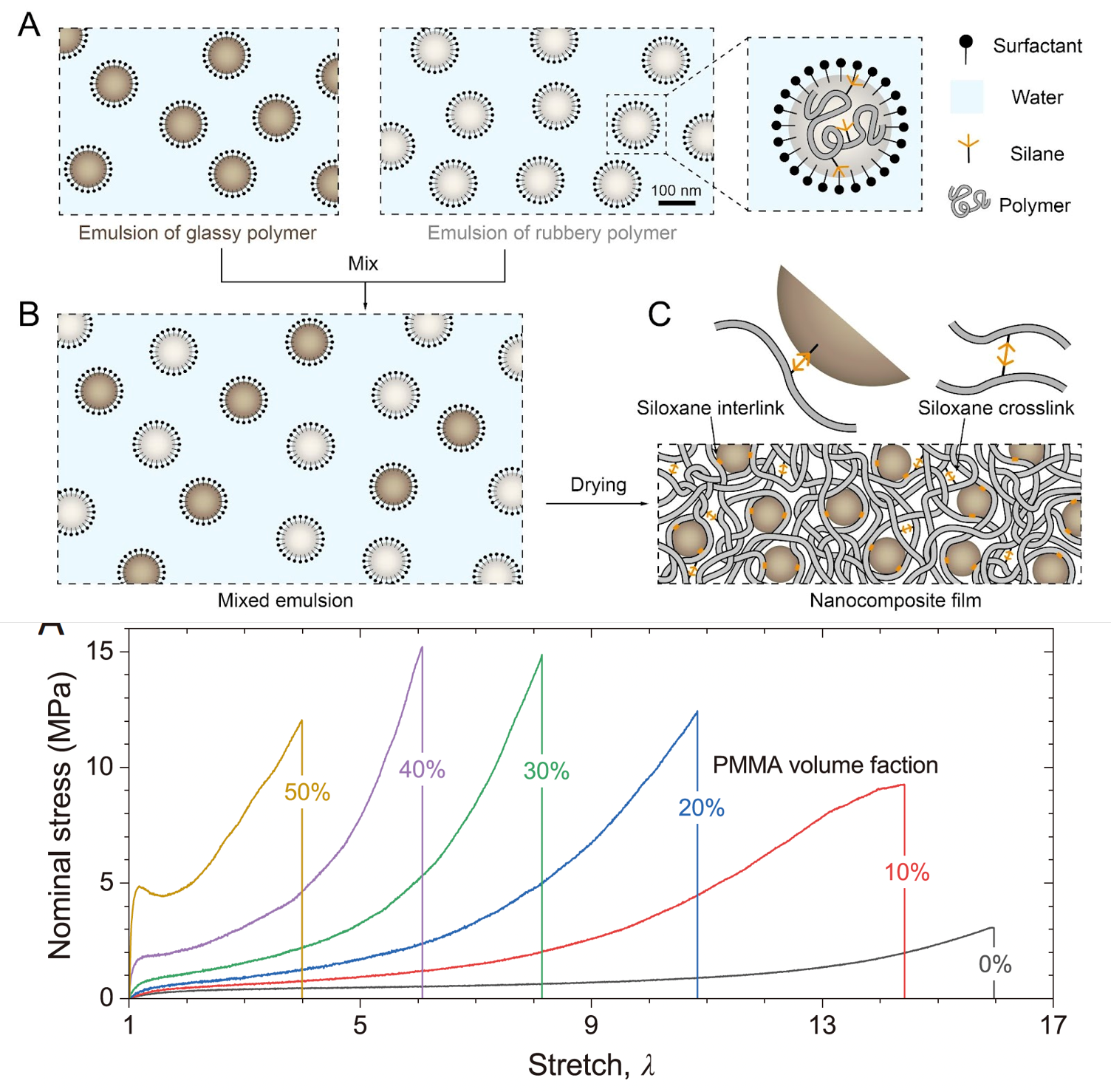

Polymer nanocomposites can be made by blending polymers, but the intense shear degrades polymer chains and, hence, resulting mechanical properties. To overcome this limitation, a Harvard MRSEC team led by Suo created polymer nanocomposites by mixing two aqueous emulsions. Each emulsion is prepared separately with a single species of polymer chains (either rubbery or glassy) in the presence of a silane coupling agent. As water evaporates, the silane coupling agent links the polymer chains together. These tunable nanocomposites simultaneously exhibit high elastic modulus, high toughness, and high fatigue threshold. This approach, based on environmentally friendly polymer manufacturing, is applicable to myriad polymers.

Publication:

Chen, Z., G. Zhang, Y Luo, Z. Suo, "Rubber-glass nanocomposites fabricated using mixed emulsion," Proceedings of the National Academy of Sciences 121 (16), e2322684121-8 (2024) ![]()

![]()

Zhigang Suo (Material Science & Mechanical Engineering)

2024-2025 Harvard MRSEC (DMR-2011754)