New Unimorph-Based Devices

Using aligned fibers to design deflection directions of dielectric elastomers

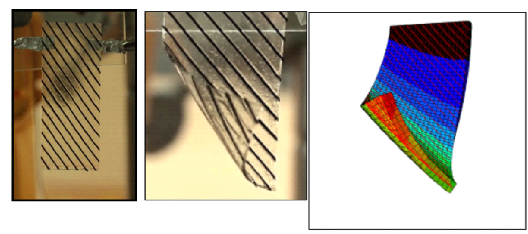

Unimorphs are flexural devices made by combining two materials as a bilayer, with one layer actuated to change shape. They represent the simplest actuation device. Unimorphs have been fabricated by bonding an active strip of piezoelectric material to a strip of passive dielectric material. When activated by an applied voltage, the strains can be so large that the deformations are no longer simple bending, but are instead a more complex curling. A Harvard MRSEC team led by David Clarke and Katia Bertoldi found that introducing elastic anisotropy by incorporating a few stiff aligned fibers into the unimorph structure could suppress out-of-plane curling. The figure shows aligned fiber unimorph before voltage is applied (left), deflection upon actuation (center) and corresponding finite element simulation (right). This discovery will help the design of unimorphs to perform important robotic functions such as "gripping" and "scooping."

�

David A. Weitz (Physics & Applied Physics)

Harvard MRSEC (DMR-1420570)