Soft Fiber Sensor Fabrication

Multicore-shell printing of textile-mounted, capacitive strain sensors

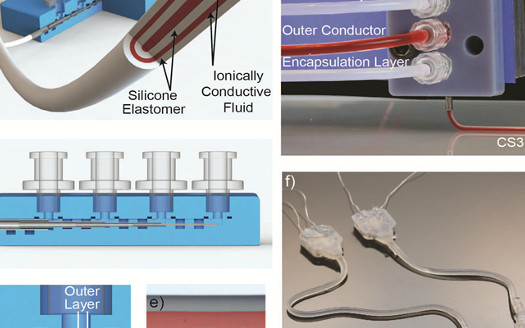

A Harvard MRSEC team led by Jennifer Lewis and Conor Walsh created textile-mounted, capacitive soft strain sensor (C3S) fibers for detecting elongational strains. Capacitive sensors typically consist of a dielectric layer sandwiched between two conductive layers, whose thickness changes with applied deformation. In a cross-collaboration between IRGs, they fabricated C3S fibers via multicore-shell printing. Each fiber consists of four concentric, alternating layers of an ionically conductive fluid and a silicone elastomer that serve as the conductor and dielectric/encapsulant, respectively [a) schematic and b) printing process in]. These materials are co-extruded in the desired configuration using a custom-designed printhead composed of four cylindrical nozzles aligned coaxially (c and d). The resulting four concentric layers produce capacitive fibers (e) whose dimensions are dictated by the relative nozzle sizes, ink flow rates, and printing speed. Using their approach, capacitive soft strain sensors (f) can be created in a flexible, highly programmable manner.

David A. Weitz (Physics and Applied Physics)

Harvard MRSEC (DMR-1420570)