Controlled Self-Assembly

of Optical Microstructures

From: C. N. Kaplan, W. L. Noorduin, L. Li, R. Sadza, L. Folkertsma, J. Aizenberg, L. Mahadevan, Controlled growth and form of precipitating microsculptures, Science 355, 1395-1399 (2017).

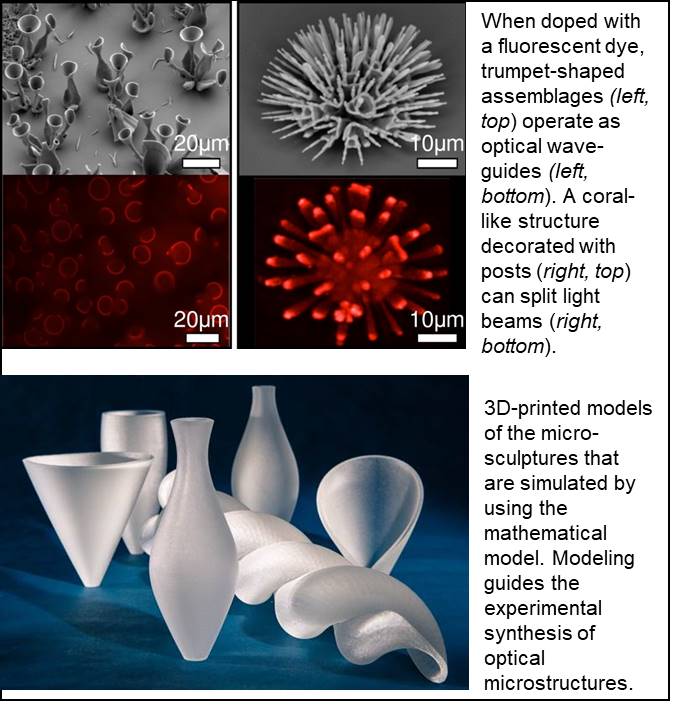

Controlled self-assembly of three-dimensional shapes holds great potential for fabrication of functional materials. Their practical realization requires a theoretical framework to quantify and guide the dynamic sculpting of the curved structures that often arise in accretive mineralization. Motivated by a variety of bioinspired coprecipitation patterns of carbonate and silica, Mahadevan developed a geometrical theory for the kinetics of the growth front that leaves behind thin-walled complex structures. The theory explains the range of previously observed experimental patterns and, in addition, predicts unexplored assembly pathways. This allowed Aizenberg to design a number of functional base shapes of optical microstructures, which they synthesized to demonstrate their light-guiding capabilities. Overall, this collaboration of experiment and theory provides a way to understand and control the growth and form of functional precipitating microsculptures.

The photograph of the 3D printed models is credited to Lori Sanders and James C. Weaver.

In nature, multi-functional materials, such as the skeletons of deep sea sponges or brittlestars, can have both complex shapes and tunable optical properties. Manufacturing analogous bio-inspired materials in the laboratory is often challenging and costly. As recently reported in Science, Mahadevan developed a geometrical theory that enabled Aizenberg to precisely control the growth and form of the minerals made of carbonate and glass in a beaker of fluid, and offers ways to tailor them for magnetic, and electronic applications. The theory further predicts new morphologies for optical applications, that were synthesized and tested.

The experimental and theoretical collaboration used the underlying physico-chemical processes in sharp contrast to top-down fabrication methods, such as lithography. The results provide a scalable, inexpensive and accurate strategy to fabricate 3D complex microstructures similar to those of biological systems which may, in turn, inspire and guide new industrial manufacturing methods.

Kevin K. Parker (Bioeng)

Harvard MRSEC (DMR-1420570)