Soft Electrostatic Patches

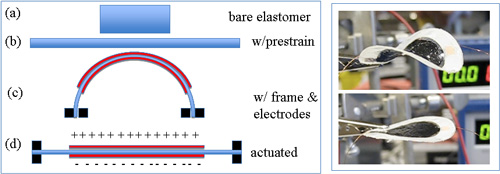

Left: Process steps for fabrication and actuation. The bare elastomer (a) is pre-strained (with user-defined anisotropy). (b) A polymer frame and compliant electrodes are attached. (c) When a field is applied. (d) The actuator changes curvature.

Right-top: With no applied field the equilibrium position for a circular frame is a saddle shape.

Right-bottom: Applied field relieves the pre-strain and flattens the actuator.

Dielectric elastomers actuators (DEA) operate by applying a field-induced stress on an incompressible (elastomeric) film. Wood achieves very large (>100%) strains, high efficiency, and high energy density possible, making this a promising technology for active soft materials. There remain many problems to overcome: high pre-strains, strain-compatible electrodes, high fields. They had preliminary success addressing each of these by design of a layered morphology consisting of the elastomer, elastic frame, liquid conductors, and thin elastomeric insulating seals. This will facilitate development of muscle-like activators.

David A. Weitz (Physics & Applied Physics)

Cynthia M. Friend (SEAS)

Robert J. Wood (Robotics), and

Michael Petralia

Harvard MRSEC (DMR-0820484)