Using Frustration to Design New Chiral Structures

for Sensing Applications

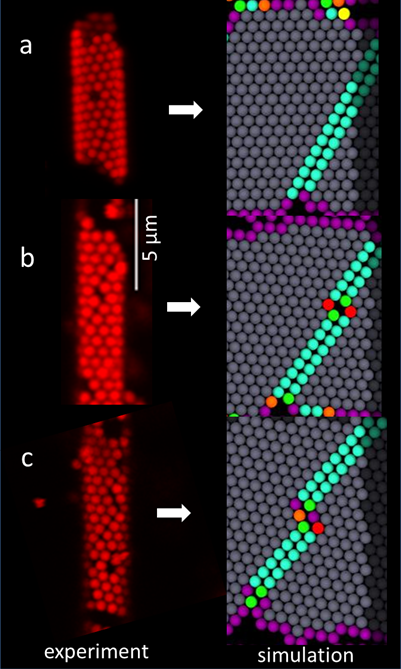

Self-assembly of "Line-slip" Structures

Self-assembly offers an alternative approach to microfabrication for making complex 3D materials. A collaboration of theorists and experimentalists at the Harvard MRSEC have demonstrated how geometry provides a powerful way to control self-assembly using frustration of crystal packing on cylinders. The team led by Manoharan, Nelson, and Rycroft studied the assembly of sub-micrometer sized spheres on the surface of a cylinder. Their experiments show that the particles form a new type of crystal known as a "line-slip" structure. These structures can take the shape of (a) a straight helical line, (b) a line with a kink, or (c) a line with a kink and gap. The helicity of the crystals and the line-slips can be tuned by using different sizes of cylinders or particles. These structures are good candidates for making chiral optical materials, with applications in sensing and cloaking.

Harvard MRSEC researchers used short-ranged depletion interaction to achieve crystallization of colloidal particles on a tapered optical fiber. For different size ratios of the particles to the cylinder, crystals form with different helicity to achieve maximum packing. For certain size ratios, a perfect crystal fails to form and then we observe line-slip defects. Line-slip defects consist of a line of particle pairs each of which has one fewer contact than in bulk. They found that the line-slips form in different shapes- one straight helical line (a), line with a kink (b), line with a kink and gap (c). Their simulations show that the kinks and gaps are results of low energy thermal excitations. This finding demonstrates that a diverse group of 3D structures can be designed by self-assembly.

Vinothan N. Manoharan (Phy & AppPhy),

David R. Nelson (Phy & Bio),

and Chris H. Rycroft (AppMath)

Harvard MRSEC (DMR-1420570)