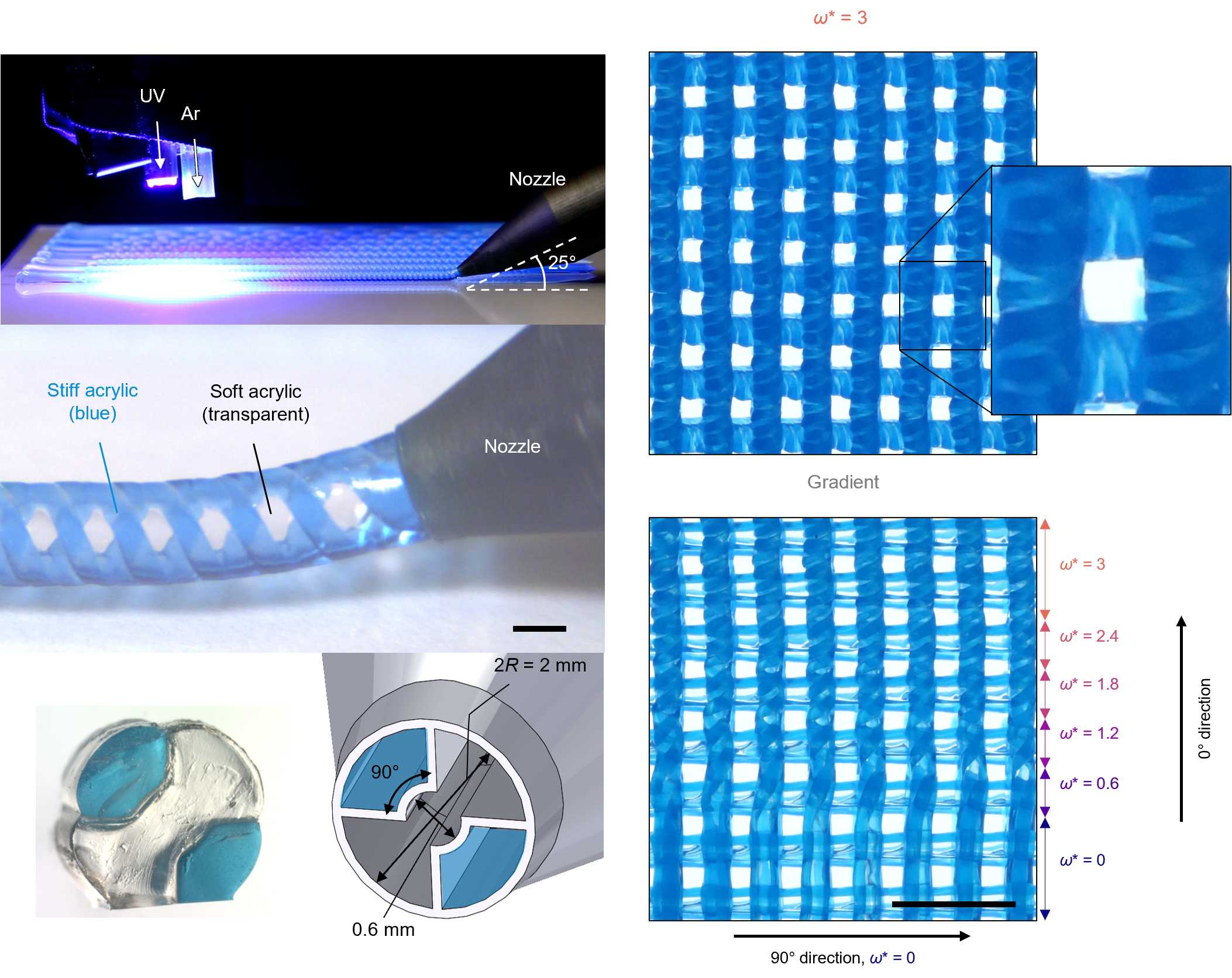

Rotational Multimaterial Printing of Springy Filaments with Subvoxel Control

Helical structures are ubiquitous in nature and impart unique mechanical properties and multifunctionality. With this as inspiration, a team lead by Lewis and Clarke have developed a new rotational multimaterial 3D printing (RM-3DP) method for patterning helical filaments in arbitrary motifs. Using RM-3DP, artificial muscles composed of helical dielectric elastomer actuators and hierarchical lattices composed of architected helical struts containing stiff springs embedded within a compliant matrix have been printed. This digital assembly platform opens new avenues to generating multifunctional architected matter in bio-inspired motifs.

Article:

Rotational multimaterial printing of helical filaments for soft robotics and structural composites

Publication:

Larson, N.M., J. Mueller, A. Chortos, Z.S. Davidson, D.R. Clarke, and J. Lewis, "Rotational multi-material printing of filaments with subvoxel control," Nature 613, 682–688 (2023) ![]()

![]()

Jennifer A. Lewis (Material Science & Bioengineering) and David R. Clarke (Material Science & Mechanical Engineering)

2022-2023 Harvard MRSEC (DMR-2011754)