Acoustophoretic Printing:

Printing Soft Materials with Sound

Thanks to gravity, any liquid can drip—from water dripping out of a faucet to the century-long pitch drop experiment. With gravity alone, droplet size remains large and drop rate difficult to control. Pitch, which has a viscosity roughly 200 billion times that of water, forms a single drop per decade.

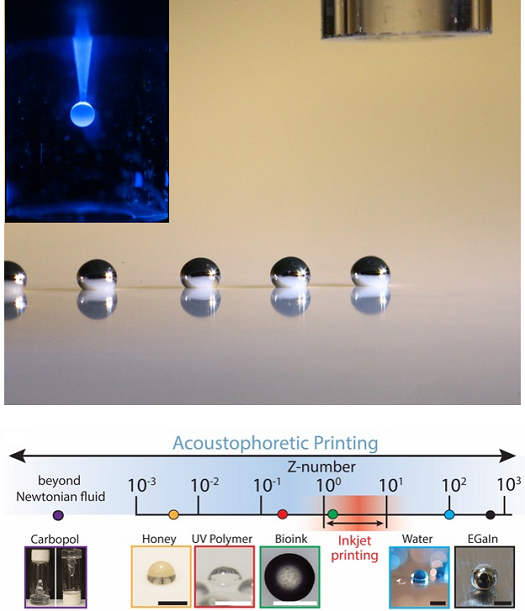

To enhance drop formation, a team at the Harvard MRSEC led by Lewis created a new printing method that relies on generating sound waves to assist gravity, dubbing this new technique acoustophoretic printing.

The researchers built a subwavelength acoustic resonator that generates a highly confined acoustic field at the tip of the nozzle. This pulling force, which can exceed 100x that of normal gravity (1 g) detaches each droplet, when it reaches a specific size and ejects it towards the printing target. The higher the amplitude of the soundwaves, the smaller the drop size, irrespective of the viscosity of the fluid.

Acoustophoretic printing enables a wide range of soft materials to be patterned, including liquid metals, polymers, and even cell-laden hydrogels.

Publication:

Foresti, D., K.T. Kroll, R. Amissah, F. Sillani, K.A. Homan, D. Poulikakos, and J.A. Lewis, "Acoustophoretic printing," Science Advances 4 (8), eaat1659 (2018) ![]()

![]()

Jennifer A. Lewis (Material Science & Bioengineering)

2018-2019 Harvard MRSEC (DMR-1420570)